Basically, electric motor or electric motor in the types of ordinary electric motor (TEFC) or another type of it, i.e. explosion-proof electric motor, as well as cooler motor, and in terms of electricity consumption, it is offered in two types of single-phase electric motor and three-phase electric motor. becomes

History of the electric motor

In 1882, Nikola Tesla established the principles of the rotating magnetic field and paved the way for the use of the rotating field as a mechanical force. In 1883, he used these principles to design a two-phase induction motor. In 1885, Galileo Ferraris independently started research on this topic, and in 1888, he presented the results of his research in the form of an article to the Royal Academy of Sciences in Turin, Italy.

The movement that Nikola Tesla started in 1888 was what some today refer to as the Second Industrial Revolution, because it led to the easier production of electrical energy and the ability to transmit electrical energy over long distances. Before the invention of alternating current motors by Tesla, motors were driven by the constant movement of a conductor through a fixed magnetic field. Tesla pointed out that the collectors of the motor could be removed so that the motor would be driven by a rotating field. Tesla was later awarded US Patent No. 0,416,194 for his engine invention. This engine, which is also in many Tesla photos, was a special type of induction engine.

In 1890, Mikhail Asibovich invented a three-phase cage rotor motor. This type of engine is widely used for various applications today.

Types of electric motors

In today's advanced machine life, there is not a person who does not come into contact with an electric motor or an electric motor or a dynamo, although he may not be aware of it. In general, wherever there is movement, there is an electric motor or an electric motor.

- DC motor

- Series engine

- Parallel motor

- Compound engine

- Self-propelled motor

- Permanent magnet motor (PMDC)

- AC motor

- Induction motor

- Synchronous motor

- Special engines

- stepper motor

- Brushless DC motor

- Hysteresis motor

- Reluctance motor

- Universal engine

Electric Motor

It is a type of machine that converts electrical energy into mechanical motion. The general idea is based on the fact that when a current-carrying conductor is subjected to a magnetic field, a force is exerted on that current-carrying conductor by the magnetic field. Most electric motors are rotary. But there are also linear motors.

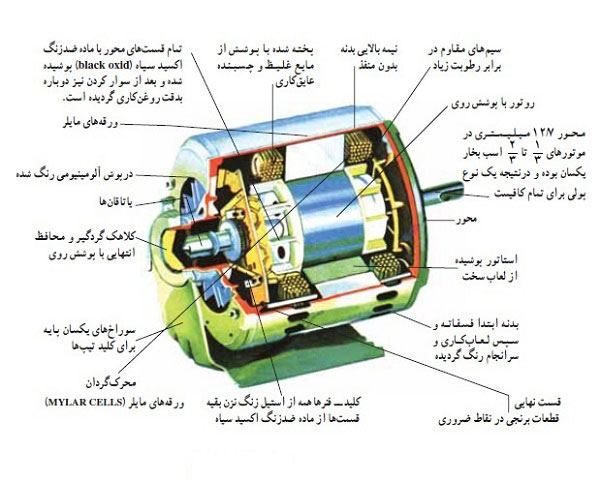

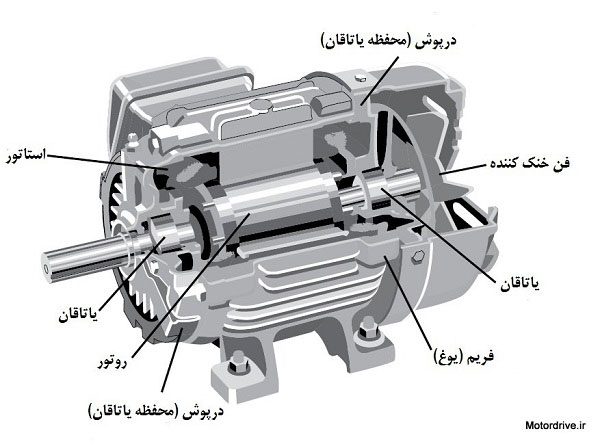

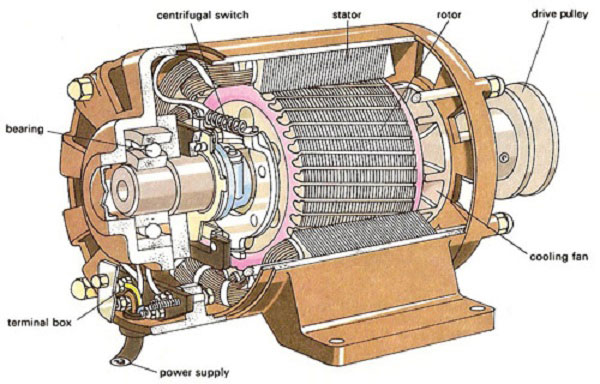

Every rotating electric motor consists of two moving and driving parts. The moving part is the rotor and the fixed part that is usually located inside the motor is also called the stator. In an electric motor, the rotor rotates around its axis due to the torque caused by the force created by the magnetic field in the stator. Each electric motor is powered by direct current DC or alternating current according to its structure.

How to choose an electric motor

The first point that should be considered when choosing an electric motor is the single-phase or three-phase voltage of the installation site. Electric motors are selected based on power and distance and installation method. If the power of the electric motor is not known, the power can be determined by considering the required output torque. The power of the electric motor is expressed in kilowatts and its torque in newton meters. The speed of the electric motor is selected according to the final speed of the mobile device and is usually 900, 1400 or 2900 rpm. Electric motors can be mounted on the base. If the electric motor is directly coupled to the gearbox or hydraulic motor, it must have a flange at the output. The flange can be produced in small (B14) or large (B5) according to the customer's needs. It should be noted that the shell of the electric motors is made of cast iron or aluminum, which is selected according to the working conditions, required weight and the amount of vibration of the device.

Definitions and terms of electricity

flow

The ratio of changes in electric charge (q) to time (t) is current and its unit is ampere (A) and it is measured by an ammeter device that is installed in series in the circuit.

Potential difference

Potential difference or voltage is a quantity that causes current to flow in a closed circuit, and its unit is volts (V) and is measured by a voltmeter that is connected in parallel in a closed circuit.

Unit of electrical work and unit of apparent power

The unit of electrical work is watt per second (W/S) and the unit of apparent power is volt-ampere (VA) or kilovolt-ampere or megavolt-ampere.

rated current

The current that an electrical device, such as an electric motor, can pass through under specified conditions, without overheating or being subjected to excessive mechanical stress.

important

If a voltage equal to 1 volt is applied to two resistors and a current of 1 amp passes through it, the resistance value is 1 ohm. The unit of electrical resistance is Ohm (Ω).

Watt

The amount of energy produced is expressed in watts. For example, light bulbs are marked with wattage, which shows how much light energy this lamp can give.

amp

Ampere is the amount of electricity flowing in a circuit. In fact, when a force causes electrons to move in a specific direction, an electric current is produced. The current (I) is expressed in terms of amperes (A).

volt

The amount of volts or voltage is the amount of electricity. In fact, it is called the electric potential difference between two points. In simpler terms, the force that moves free electrons is called electric voltage. Electric potential difference (R) is expressed in volts (V).

Magnetic field

The electric field at any point is defined as the force acting on the unit test charge q0. In other words, to determine the electric field E, we divide the force F by the charge q0.

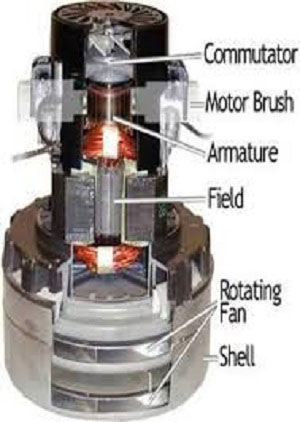

Components of electric motors

First, let's take a look inside a simple electric motor. A simple electric motor consists of 6 parts:

- armature

- Conductive coal

- Power direction switch

- axis

- magnet

- DC power supply

Types of electric motors or electromotors are divided into two main categories in terms of current consumption:

- Electric motor or electric motor (Direct Current) or DC direct current

- Electric motor or electric motor (Alternative Current) or AC alternating current

What are DC or direct current electric motors?

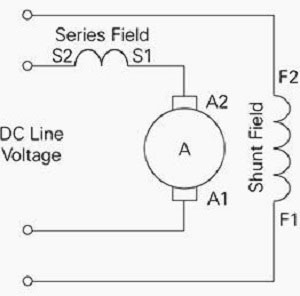

DC motor or direct current; It has an armature of an electromagnet. A rotary switch called a commutator reverses the direction of the electric current twice in each cycle to create electromagnets in the armature that attract and repel the permanent magnet outside the armature. The rotation speed of the DC motor depends on the braking torque, in other words, it depends on the input voltage and the input current torque.

- Series DC electric motor

DC series motors have a high starting torque and are therefore used in industries that require high starting torque (such as cranes, hydraulic lifts, impact presses and elevators). Also, this type of dynamo is used in city locomotives (metro and tram), which is called traction motor.

- Shunt DC electric motor

Shunt or parallel DC motors have maximum torque at rated speed. Therefore, it is used in applications such as industrial ventilators and blowers. This type of electric motors should not be started under heavy load, because their armature current increases too much and damages the motor.

- Compound DC electric motor

In compound motors, there are characteristics of series and shunt motors and they include two categories.

1. Additional compound DC electromotor

This type of electric motor is used in cases where the characteristics of a series motor are required, but when the load is removed, the motor cannot be stopped and its speed does not increase too much. Like lathe machines, which are unloaded and loaded again in every working period. In various industries, it is usually used instead of using an additional compound dynamo whose design is similar to series electric motors.

2. Defective compound DC electric motor

At loads lower than nominal loads and in cases where almost constant speed is needed, compound motors are used. These motors are usually used in laboratories to provide constant speed.

What are AC or alternating current electric motors?

The most common type of alternator used in industry and home are AC induction motors.

Advantages of using AC electric motors

- Simple and solid design

- Reasonable price

- Low maintenance cost

- Easy and complete connection to a power source

There are many different types of AC or induction motors in the industry. Different electric motors are suitable for different tasks. Although AC motor design is easier than DC electric motor, but controlling the speed and torque in different types of AC electric motor requires a deeper understanding of the design and specifications of these types of motors.

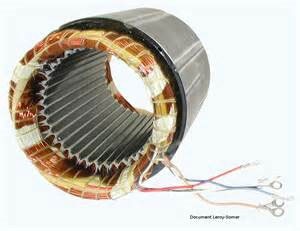

Stator

The stator is made of several thin pieces of aluminum or light iron. These parts are stapled together as a hollow cylinder. Coils of coated wire are embedded in these grooves. Each coil group with the core surrounding it forms a magnetic magnet (double-bridged) to operate on AC power. The number of poles in an AC motor depends on the internal connection of the stator windings. The stator coils are directly connected to the power source. They are connected in such a way that a rotating magnetic field is generated when AC power is applied.

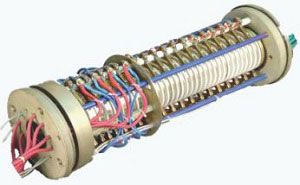

rotor

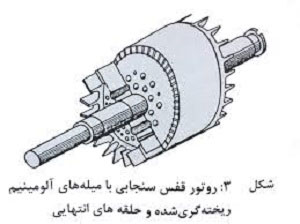

The rotor is made of several separate thin steel pieces with copper or aluminum rods inserted between them. In the most common type of rotor (squirrel cage rotor), these rods are electrically and mechanically connected by rings at their ends. Almost 90% of electric motors have a squirrel cage rotor and this is because this type of rotor has a strong and simple structure. This rotor consists of a multi-piece cylindrical core with an axis that has parallel slits to insert the conductors inside. Each slot contains a copper or aluminum or alloy rod. In these rods, a short circuit is permanently established by their end rings as seen in Figure 2. Because this type of assembly looks just like a squirrel cage, this name was chosen for it. The rotor bars are not exactly parallel to the axis. Instead, they are installed somewhat reluctantly for two important reasons.

- The motor is operated without sound by reducing the magnetic sound and to reduce the harmonics in the gaps.

- Reduce the tendency of the rotor to hang. The rotor teeth try to stay in front of the stator teeth due to direct (sheer) magnetic attraction. This happens when the number of rotor and stator teeth are equal.

Types of AC electric motors

- Synchronous AC electric motor

- Asynchronous AC electric motor

Synchronous AC electric motor

In synchronous alternators, the rotor and stator are wound. When the stator is connected to the power source, a rotating field is created in the motor, which rotates at synchronous speed. The rotor is also wound which is powered by a DC source. By connecting the DC current to the rotor, the rotor starts rotating with the rotating field of the stator. To start the synchronous electric motor, first the electric motor rotates at the synchronous speed after the primary driver is cut off.

Application of synchronous electric motor

- This product is for correcting the power factor (Cosφ). In this case, no load is placed on the axis of the synchronous motor, that is, the electric motor works without load. In this case, the synchronous motor is also called a synchronous capacitor and is used in factories.

- These motors can be used both as a synchronous generator and as a synchronous electric motor.

- Because the synchronous electric motor has a fixed speed, it is used in equipment such as electric watches that require this feature.

Advantages of synchronous electric motor

- It is not sensitive to voltage fluctuations.

- It has a very high yield.

- It has a suitable and adjustable power factor.

- This electric motor can work directly with high voltage.

Weaknesses of synchronous electric motor

- The speed of this electric motor is fixed and cannot be adjusted for higher or lower speeds.

- This electric motor cannot bear extra load.

- In addition to alternating current for the stator winding, permanent current is also required for the poles of this electric motor, thus increasing the price of this electric motor compared to similar items.

- It needs an initial starting device which can be an auxiliary engine.

Asynchronous AC electric motor

- Squirrel shelf

- Coiled rotor (Slip Ring)

What is asynchronous AC electric motor squirrel cage?

The rotor of squirrel cage motors is cylindrical in shape, with aluminum or copper rods inside iron or steel peripheral grooves, which are made in two ways, the first type is made of round rods and the second type is rectangular rods. Or it is formed in the form of two circles that are connected or separated from each other. The rotor rods of the electric motor are designed diagonally so that the impact of the stator fields on the rotor creates a kind of overlap and avoids vibration or locking at the moment of starting.

Advantages of squirrel cage asynchronous electric motor

- Due to its reasonable price and simplicity in design, it has replaced other engines in many industries.

- The rotation speed of this dynamo is almost constant in different loads.

- Changing the load does not cause this type to stop moving.

- Compared to slip ring electric motors, they have a better power factor.

Weaknesses of squirrel cage asynchronous electric motor

- When it is working with little work, its power factor is reduced.

- It is impossible to change the circuit of this type with the voltage reduction method and it requires a device (AC Drive) for this task.

- Squirrel cage asynchronous electric motors are sensitive to voltage changes, and if the voltage decreases, the current will increase accordingly.

- It has low torque.

- At the start of this electric motor, they take a lot of current from the network, about 3 to 7 times the rated current.

Asynchronous AC electric motor with coil rotor

The problem of squirrel cage motors is the very low resistance of its rotor. The rotor bars are short-circuited by a ring at the beginning and end. This issue at the moment of starting, when the rotor is not magnetic, the flux (the electric field lines that pass through the surface perpendicular to the path are called electric flux) attracts a lot to be magnetized and causes the current of the electric motor to rise, as a result in The starting moment takes a lot of current from the network and causes a decrease in the starting torque. In order to solve this problem, wound rotor electric motors were designed and built, which solved this problem to a large extent.

In these coiled rotor products, instead of having a rod in the rotor, the rotor is coiled and the ends of these coils are connected to the sliding rings that are guided to the outside of the motor by brushes. By placing resistance banks (starter) in the way of these coils, the resistance of the rotor can be increased or decreased and the current draw of the motor can be changed as desired.

Resistance bank, starter or starter

The starter has three steps to bring the engine to the rated speed. The first stage of the resistance bank is removed from the circuit by the related contactor when the engine reaches 30% of the rated speed and the alternator continues to rotate. The next steps are at 50% and 75% of the nominal cycle. After this cycle, the starter is completely removed from the circuit and the engine is directly connected to the network and reaches the nominal cycle.

Coiled rotor electric motors are used in mills, stone crushers, cranes and in cement and steel industries.

Advantages of AC asynchronous motor winding rotor

- The heat generated occurs outside the starter.

- This dynamo has the ability to start consecutively and under load.

- The starting current of the electric motor is adjustable.

- Winding rotor electric motors have maximum torque at the moment of starting.

AC electric motor

AC motors, like most electric motors, have an external fixed part called the stator and a rotor that rotates inside. Electric motors use a rotating magnetic field to virtually turn their rotor. A three-phase AC electric motor is the only type in which the rotating magnetic field is naturally generated by the stator due to its feeder nature. While in DC motors, they need an electrical or mechanical device to produce this rotating field. To start a single-phase AC electric motor, an external electrical device is needed to generate this rotating magnetic field. Inside each AC motor, there are two sets of magnetic magnets.

Types of electric motors (types of dynamo)

- Single phase electric motor

- Three-phase electric motor

Electric motors are usually divided based on the number of stator coils.

Single phase electric motor

In this model of heavy-duty electric motors, a coil is used and it works with a single-phase alternating power supply. The single-phase motor is not self-starting, and in all types of single-phase electric motors, the rotor is of the squirrel cage type. When the motor is connected to a single-phase power supply, the main winding has an alternating current. This alternating current produces a pulsating magnetic field. Due to induction, the rotor is excited. The single-phase electric motor needs a starter device that can produce the starting kicks for the motor to rotate.

When the supply voltage is established, the current in the main coil drops the supply voltage due to the resistance of the main coil (voltage turns into current). Meanwhile, the current in the starter coil turns into an increase in the supply voltage depending on the resistance of the starter device. The interaction between the magnetic fields that make the main coil and the starter device (including the auxiliary coil and capacitor) creates a resultant field that rotates in a direction. The axis of the electromotor starts to rotate in the direction of this resultant field. When the engine reaches 75% of its permitted speed, a centrifugal switch takes the starter coil out of the circuit. From this moment on, the single-phase electric motor can maintain enough torque to continue its operation.

Types of single-phase electric motors

The types of single-phase dynamo are:

- Single-phase AC electric motor with broken phase

- Single-phase AC electric motor with capacitor start

- Single-phase AC electric motor with permanent spilt capacitor

Single-phase AC electric motor with broken phase

This type of single phase motor has two coils. In the starter coil of this alternator, thinner wire and fewer turns are made than the main coil to create more resistance. The starting coil is located at a different angle from the main coil to start the rotation of the electric motor axis. The main coil is made of thicker wire. This electric motor is suitable for jobs with low starting torque and required power of 1/20 to ⅓ horsepower, and these electric motors are not suitable for applications that require continuous turning on and off or high torque.

Single-phase AC electric motor with capacitor start

This type is the modified broken phase model with a series capacitor to improve the start and has a higher starting torque due to the higher density of the wire in the starter circuit.

Electric motor with resistance start

The improved type of the capacitor start electric motor is also the electric motor with a resistance start, in which the start capacitor is replaced by a resistor. The electric motor with a resistance start is used in applications where the amount of starting torque is lower than the amount produced by the electric motor with a capacitor start. Regardless of the cost, this industrial electric motor does not have major advantages over the electric motor with capacitor start. These motors are well used in various types of pulley and belt applications such as small conveyor belts and in pumps, large blowers and gear applications.

Single-phase AC electric motor with permanent split capacitor

This type of electric motor has a type of capacitor that is permanently connected in series with the starter coil. This causes the starter coil to act as an auxiliary coil until the electric motor axis reaches its rated rotation speed. Since the main performance capacitor must be designed for continuous use, it cannot create a starting power equivalent to a capacitor start electric motor. The starting torque of a single-phase electric motor with a permanent capacitor is usually low and around 30 to 150% of the rated torque.

Single-phase AC electric motor with capacitor start/capacitor operation

This type, like a motor with a capacitor start, has a starter type capacitor in series mode with an auxiliary coil for high starting torque. Also, like an electric motor with a permanent capacitor, it has a capacitor of permanent operation type, which is in series with the auxiliary winding next to the start capacitor, which is removed from the circuit after the electric motor starts working. This condition causes additional torque. This type of electric motor can be designed for higher efficiency.

Single-phase AC electric motor with shaded pole (with short circuit ring)

Types of single-phase electric motors with shaded poles have only one main coil and no starter coil. Starting is done by its special design that wraps a continuous copper ring around a small part of each pole of the electric motor. This shadow that splits the pole into two pieces causes a weaker magnetic field to occur in the shadowed area than the other part next to it. The interaction between the fields makes the axis rotate.

Three-phase electric motor

برای کاربردهای نیازمند به توان بالاتر، از الکتروموتور سه فاز AC (یا چند فاز) استفاده می شود. الکتروموتور سه فاز از اختلاف فاز موجود بین فازهای منبع تغذیه چند فاز الکتریکی برای ایجاد یک میدان الکترومغناطیسی دوار درونشان، استفاده می کنند. اغلب، روتور شامل تعدادی هادی های مسی است که در فولاد قرار داده شده اند. از طریق القای الکترومغناطیسی میدان مغناطیسی دوار در این هادی ها القای جریان می کند، که در نتیجه منجر به ایجاد یک میدان مغناطیسی متعادل کننده شده و موجب می شود که محور الکتروموتور در جهت گردش میدان به حرکت در آید.

In order for the axis of the three-phase electric motor to move, the axis must always rotate at a speed lower than the frequency of the power source applied to the electric motor. Otherwise, the balancing field in the rotor will not be created. The use of this type of industrial electric motor in traction applications such as locomotives, where it is known as asynchronous traction motor, is increasing day by day. A separation field current is applied to the rotor windings to create a continuous magnetic field, which is present in the synchronous electric motor, the electric motor rotates synchronously with the rotating magnetic field generated by the three-phase AC power. Synchronous electric motors can also be used as current generators.

The speed of an AC motor depends primarily on the supply frequency, and the amount of slip, or the difference in rotational speed between the rotor and the stator magnetic field, determines the torque produced by the motor. Changing the speed in this type of industrial electric motor can be made possible by having a bunch of different coils with different number of poles in the stator section, which use them to change the speed of the rotating magnetic field. Also, by changing the frequency of the power supply, you can have a more uniform control over the speed of this type of electric motor.

Types of three-phase electric motors

The types of three-phase dynamo are:

- Squirrel cage three-phase electric motor

- Squirrel cage three-phase electric motor with coiled rotor (slip ring)

Squirrel cage three-phase electric motor

Almost most types of three-phase AC electric motors are of this type, whose rotor is squirrel cage type. Their power classification ranges from ⅓ to several hundred horsepower. The three-phase electric motor of this type, which is in the range of 1 horsepower and above, is cheaper compared to similar single-phase electric motors and can work with heavier loads at the time of starting.

Squirrel cage three-phase electric motor with coiled rotor (slip ring)

این الکتروموتور نوعی از موتورهای قفسه سنجابی است که موتور با حلقه لغزان یا با روتور سیم پیچی شده است. در حالی که استاتور در این الکتروموتور سه فاز همانند الکتروموتور قفس سنجابی است، یک سری از پیچه ها را روی روتور خود دارد که در حالت مدار کوتاه نیستند ولی به یک سری از رینگ های لغزان ختم می شوند. این الکتروموتور صنعتی در کاربری هایی با چرخش با گشتاور و سرعت های مختلف مانند پرس های چاپ، کمپرسور ها، تسمه نقاله ها، بالابر ها و آسانسورها مورد استفاده قرار می گیرد.

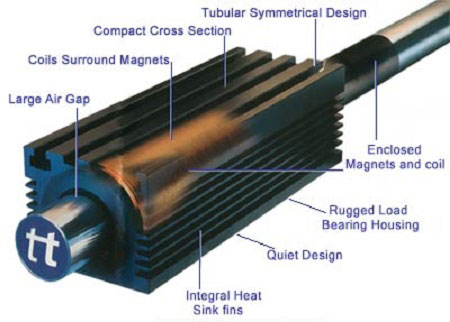

Linear electric motor

A linear motor is basically an electric motor that has been converted from rotary to produce a linear force by creating a traveling electromagnetic field along its length instead of producing a rotational torque. Linear motors are often induction or stepping motors.

Stepper motor or servo

Another type of electric motor is the stepper motor or servo motor, in which an internal rotor, consisting of permanent magnets, is controlled by a set of magnets with external on-off electronic control. A stepper motor is a combination of a DC motor and a solenoid. Simple stepper motors are held in certain positions by part of a gear system, but controlled stepper motors can rotate very slowly. Computer controlled stepper motors are one form of positioning system, especially when they are part of a digital system with load command control.

A guide to choosing the right electric motor

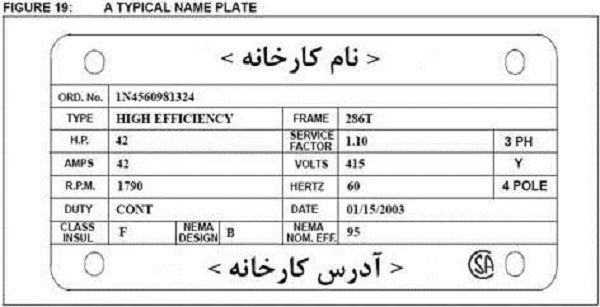

How to read the license plate of the electric motor

On all kinds of electric motors, a plate is installed by the factory, on which all the information of the electric motor for starting is given, and if the declared items are not followed correctly, the electric motor will burn or its useful life will be reduced.

- No: The engine model that is usually specified by the factory.

- Type: engine name, by having the engine name and referring to the manufacturer, you can get more information about the engine.

- AMPS: is the virtual maximum current that the motor needs to operate.

- V: is the working voltage of the electric motor, which should not be applied more or less voltage to the coils of the industrial electric motor. If there is an asterisk (Y) or triangle (Δ), the voltage is used in the same connection (for example, the working voltage of the above motor is 415V in star mode).

- HERTZ: specifies the working frequency of the motor, usually the working frequency of the motors is 50 or 60 Hz.

Note: The speed of an electric motor is related to its frequency. Therefore, the electric motor, which supposedly has 1500 revolutions at the frequency of 50 Hz, does not have 1500 revolutions at the frequency of 60 Hz.

- DATE: It specifies the engine manufacturing date.

- R.P.M: indicates the rotation of the electric motor in one minute on the output power.

- KW: shows the power value of the electric motor.

Note: If it is written on the electric motor 220/380 V, it means that this electric motor is used in the 110 volt grid that is used in some countries, and in countries that have 220 volt voltage (voltage between one phase and zero) Like Iran, it should be closed as a star.

- IP = the degree of protection of the electric motor against dust according to the table below.

- P.H = types of protections according to DIN 40050 standard

- P00 = open without protection against contact with foreign objects and water, in this case the motor must be kept in a covered space.

- P10 = Protected against hand contact and large foreign objects - protected against water, the engine can work in the arm space under rain.

- P11 = Protected against hand contact and large foreign objects - Protected against water

- P20 = Protected against finger contact and medium-weight objects without protection against water, a suitable cover must be provided for the motor.

- P21 = Protected against contact with fingers and objects with medium weight - waterproof

- P22 = Protected against finger contact and objects with medium weight - Protected against water discharge vertically or obliquely at an angle greater than 30 degrees to the horizon

- P30 = Protected against contact with tools etc. and lightweight foreign objects - no protection against water

- P31 = Protected against contact with tools, etc., and lightweight foreign bodies - waterproof

- P32 = Protected against contact with tools, etc., and light-weight external objects - Protected against vertical or inclined water discharge at an angle greater than 30 degrees to the horizon

- P40 and above: Protected against all external factors

There may be other information on different types of electric motors. The user can find out about them by referring to the engine catalog.

The standard defined in relation to the IP of electric machines

The letter W is used after the two declared digits in cases where the electric machine is designed with an open circuit with an air cooling system and works in atmospheric conditions in such a way as to prevent the penetration of rain and wind-borne particles under certain conditions. The electric machine reduces and controls, and the small amount of input inside does not affect its performance, such as IP13W.

When only one feature of the IP indexes is important for the consumer, the unimportant index is marked with the letter X, such as IP2X, which only indicates the degree of protection against life, or IPX4, which indicates the degree of protection against moisture.

The first digits: the degree of life protection defined and its characteristics

- 0: The machine is not protected.

- 1: Protected against human hands or objects with a diameter of more than 50 mm

- 2: Protection against human fingers or objects with a diameter greater than 12 mm

- 3: Protection against electric tools with a diameter greater than 2.5 mm

- 4: protection against thin wires and insulation with a diameter of more than 1 mm

- 5: Protection done inside the electric machine against excessive dust that is harmful to it.

- 6: Complete protection against dust

The second digits: the degree of protection against moisture defined and its characteristics

- 0: The machine has no protection against moisture.

- 1: The electric motor is protected against water dripping vertically.

- 2: The electric motor is protected against water dripping with a deviation of 15 degrees from the vertical.

- 3: The electric motor is protected against water leakage.

- 4: The electric motor is protected against splashing water.

- 5: The electric motor is protected against water ingress.

- 6: The electric motor is protected against flooding.

- 7: The electric motor is protected against the destructive effects of immersion.

- 8: The electric motor has the ability of permanent immersion in water.

| Technical terms | IEC standard | Standard equivalent to DIN |

|---|---|---|

| Nominal values and performance characteristics | 60034-1 | – |

| degree of protection | 60034-5 | 40050, 40051, 40052 |

| Cooling method | 60034-6 | – |

| How to install | 60034-7 | 42950 |

| Terminal marking and direction of rotation | 60034-8 | 42401 |

| Noise limits | 60034-9 | 45635 T 10 |

| Launch performance specifications | 60034-12 | – |

| Limits of vibrations | 60034-14 | – |

| Standard voltage | 60038 | – |

| Dimensions and rated output power | 60072 | 42673, 42677 |

| Insulation material | 60085 | – |

| Installation flange | – | 42948 |

| Thorn on the shaft | – | 6880 |

| Gland used in the terminal | – | 46320 |

Standards used in electric motors

Conversion coefficients for operation at a frequency of 60 Hz

| Rated speed | rated power | rated current | Startup flow |

|---|---|---|---|

| 1.2 | 1.2 | 1.2 | 0.83 |

The conversion coefficients of the conversion work at 60 Hz

In the condition that motogen electric motors with rated load are used at an altitude of more than 1000 meters above sea level, the output power of the electric motor must be modified according to the following table:

| Height above sea level (meters) | Maximum output power (percentage) |

|---|---|

| 1000to 2000 | 95 |

| 2000to 3000 | 88 |

| 3000to 4000 | 80 |

Motogen engine output power based on altitude

In conditions where the ambient temperature is more than 40 degrees Celsius, the output power of motogen electric motors is modified according to the following table:

| Ambient temperature (C) | Maximum output power (percentage) |

|---|---|

| 40 تا 45 | 95 |

| 45 تا 50 | 88 |

| 50 تا 55 | 80 |

Table of correction coefficients related to ambient temperature

Thermal insulation class of electric motor

According to the standards set by the International Association of Electrical Equipment Manufacturers or (NEMA) NATIONAL ELECTRICAL MANUFACTURES ASSOCIATION

The insulation of electric motors is defined in four classes (A, B, F, H) according to the temperature of the motor in different working environments, and based on this standard, the ambient temperature is considered to be 40 degrees Celsius, and the temperature Determined with a maximum efficiency of 10 degrees for the hottest spot in the screw center (HOT SPOT).

- Class A: up to 105°C

- Class B: up to 130°C

- Class H: up to 155°C

- Class F: up to 180°C

Brands that can be sold in Tun Sazan

| TEFC electric motor brands | |

|---|---|

|

|

| برندهای الکتروموتور ضد انفجار (EX) TEFC | |

|---|---|

|

|